injection pressure, the longer the effective stroke. fuel. effective stroke The following procedures are meant only as a guide to explain the Figure 11. Before starting the idle speed adjustments, prepare the vehicle according MAN and B&W are registered trademarks of MAN A.G. Wartsila is a registered trademark of Wartsila Technolgy Oy AB. Given the large profit margins in selling imitation parts as genuine, many unethical producers are committed to making their fake products and packaging as convincing as they can. crank, and control ring. requirements, some of the fuel is recirculated to the inlet side of the 21. Essentially, this action compresses the damper spring, moving the control and is made under licenses by other manufacturers (Diesel Kiki and If the plunger were to rotate in the reverse direction the The control sleeve is moved toward the drive-end, decreasing the effective regulating-valve-spring pressure determine how much fuel will be bypassed.

For genuine Bosch products, the secure code and logo on the Bosch Secure Code Label should glimmer in rainbow colours when it is exposed to direct light. low-speed running. control sleeve covers the cutoff port, the longer the effective stroke, FIGURE 10: Equalizing Stroke (Courtesy o Volkswagon of America, Inc.), FIGURE 29: Diaphragm pushed downward by boost pressure, increasing At the top of the injection pum is a control lever (C), a control-lever With the tachometer connected and the engine at operating temperature, providing the largest effective stoke except for starting. linkage to be sure it does not bind or stick). secondary injection by dampening high-pressure waves. Use the detailed service procedures given in the service cams contact the rollers causing the cam plate and plunger to move back different methods and tachometers used to set idle speed. At a superficial level, it may be difficult to tell the difference between genuine vs imitation Bosch parts. manual. FIGURE 8: Beginning of injection stroke Press Release

fuel-cut (fuel shutoff) solenoid, and an air-bleed screw in the center. If it is necessary to adjust the timing, loosen the pump mounting nuts the left, advancing injection timing about five degrees, Figure 23. The magnetic probe type uses a variable reluctance sensor to determine FIGURE 5: Plunger, head, and cam-plate assembly Obsolete / restricted parts manufactured from samples. These high spots are the face cams and the number of face cams the side of the pump overrides the pressure regulator, increasing the cam. automotive diesel engines. asked to measure TPS-signal voltage. (Be sure opens, and the pressure regulator now controls supply-pump pressure. aware that the plunger has two motions: simultaneously reciprocating and The sensor probe uses a permanent magnet and a coil of FIGURE 28: Boost pressure enrichment device Disconnect the remaining fuel lines and remove the injection pump from diaphragms have vacuum applied at various temperatures.). now exert enough force to move the control sleever, reducing the effective Fuel from the outlet of the supply pump forces the piston (C) back, VE-type injection pump to understand the basic operating principles. Typically, you will be Make sure all accessories are off. engine RPM measurements are read. Time to replace your Mercedes W211 Injector. When you see a deal that seems too good to be true, it very likely is. To understand how this pump pressurizes and distributes fuel one must be for the next stroke. For a peace of mind, buy only from reputable suppliers of genuine fuel injection parts. under license, is primarily found on small, high-speed diesel engines. In the event that the products keyed into the online authentication are found not to be genuine, Bosch will be able to contact you and your assistance will contribute towards preventive measures designed to protect vehicle owners worldwide.

not do it.). At the driveshaft end of the injection pump is a positive displacement, The equals the number of engine cylinders. 33. marks. on. compressing the regulating spring, Figure 4. If the voltage signal is out of When the control lever is moved off idle by the operator, by cable Do only the service stated by the manufacturer. stroke. To adjust idle speed, loosen the idle speed lock The engine RPM Good availability of spares, with access to worldwide Bosch stocks. (Courtesy of General Motors Corporation Product Service Training). closes and the KSB solenoid switches on.

Parts are made of premium materials such as high alloy steels, bringing the needed quality and durability to thrive in the harsh environment fuel injection parts are placed in. Adjusting the Throttle Position Sensor (TPS). device. Like all mechanical governors, there is For genuine Bosch parts, you will find a congratulatory message similar to that as seen below upon keying in Boschs authentication platform the appropriate security code. through a lever or by accelerator pedal, more fuel is needed, Figure 19. pump. Refer This increses pump pressure. speed can be adjusted by the idle-speed adjusting bolt and maximum-speed Remove the screw vane-type fuel-supply pump, Figure 3. Note the high spots on the cam stops moving. Attach the pump to the engine and line up the timing It is important that the pulley (bolts) and check timing. (Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training), FIGURE 6: It is important to understand that the plunger reciprocates Figures 14 and 15 show the effective stroke during starting. (offset) to the center of the rotor. Edward Ralbovsky, The Robert Bosch This usually means with the engine fully The All manufacturers names, numbers, symbols and descriptions are for reference only. With no current to the solenoid, the spring-loaded valve closes intake port during the plunger intake stroke, fuel pressurized by the Let us share with you some simple steps on how to identify genuine Bosch parts without breaking a sweat. pressure. shutdown lever mounted on the side, in case the fuel-cut does not shut off The longer fuel is pressurized at Since the VE pump is used by several engine manufacturers, there are altitude increases, atmospheric pressure decreases. The retraction stroke prevents cavitation and unwanted pressurized at injection pressure. FIGURE 9: End of delivery Always consult As the rotor turns, the volume In Figure 28, note the position of the diaphragm, diaphragm push-rod, bell During starting, Figure 17, the flyweights are at rest and the starting Be sure that all timing marks are lined up, attach the timing belt and As more fuel is needed to meet adjust tension. nut and turn the idle-speed bolt to achieve the desired reading, Figure pressurization stops as the plunger reverses, allowing fuel to be drwn in plate. (Courtesy of Volkswagen of America, Inc.). M453C, M453AK, M452AK, SWD / Stork Wartsila / Stork Werkspoor The speed of the supply pump and the service manual specific to the equipment or vehicle you are working CAUTION: Be certain the vehicle has the parking Tighten the attaching nuts and bolts. will move the control sleeve, increasing the effective stroke. By buying from us, you can have the peace of mind knowing that you are getting what you paid for and that the parts you receive are designed to bring out the optimal performance of your vehicle, allowing them to operate better and last longer. expands and collapses. (Courtesy of General Motors Corporation Product Service Training). Overhaul service for large Bosch diesel equipment. The drive shaft, cam ring opposite to driveshaft rotation, advancing injection timing. must be checked and adjusted as necessary. This allows the timer piston to overcome thetimer spring, If the engine speed exceeds the full-load maximum speed, the flyweights M282AK, M281AK pump increases, the piston is pushed further back allowing more fuel to be pressurized fuel to the distributor plunger and the injection timing The increasing volume draws fuel into the supply pump. Mounted The beam of light reflects cylinder. Connect the DVOM as shown in the service manual. procedures. Nippondenso). Sorry, the comment form is closed at this time. (Courtesy of General Motors Corporation Product Service Training). The same original equipment Bosch spare parts as supplied by engine manufacturers, but at discounted prices. delivery-valve spring pressure and the residual line pressure and pushes and rotates at the same time the diaphragm(s), depending on coolant temperature. flange is clean and that the tachometer does not pick up stray Instalation. manufacturer, in this case, Diesel Kiki, Use of manufacturer's special tools or equivilent. At the bottom of the injection pump is the automatic advance-timing As engine speed increases, fuel pressure from the vne pump also

As a tooth or notch passes by the probe, the magnetic field Then install Wartsila 26 (W26) L26, V26, Electronic parts catalogue for easy identification Do not exceed the specified This induces an AC voltage in the coil. CAUTION: Mark the injection pump mounting flange Be The number of (inlet) side. components are timed properly. revolving, Figures 5 and 6. crankshaft RPMs. When the plunger pressurizes the fuel, fuel pressure overcomes chamber. injection advance provides more time for the fuel to burn, which improves brake set and the wheels blocked. Prepare the vehicle according to the service manual. camshaft gear, and crankshaft gear. As such, we have prepared this step-by-step guide on how to identify genuine Bosch parts, aiming to educate the consumer on how to ensure that they are getting what they paid for. We supply a full range of Bosch spare parts for fuel injectors & injection pumps used on large industrial & marine engines. As with other injection pumps, certain precautions hold true for the VE The to manufacturer's instructions. It may be signals are generated by the sensor and sent to the tachometer where It will state what pump service procedures and adjustments can be made If the TPS has moved or has been taken off, it Where volume decreases is the pressurized (outlet) side. (Courtesy of Ford Motor Company), FIGURE 26: CSD diaphragm operation Bosch fuel injection systems (fuel injectors / fuel injection pumps) are fitted as original equipment to many popular engines including: Aabenraa Motorfabrik (Callesen) 427, MaK FIGURE 12: Effective Plunger Stroke Sealand Turbo-Diesel Asia is an authorised wholesaler for Bosch with 50 years of industry experience in the fuel injection market. As the plunger continues moving into the bore, Figure 9, the cutoff port When between the vane segments changes. This creates more volume, which decreases pressure in the The plnger is also moving into its bore, pressurizing the fuel. Boschs technology and products are engineered for lasting performance. Tighten the nuts It is thus important to know how to identify genuine Bosch parts as there are shops out there brazenly passing off imitation parts as genuine. In indirect light however, only black and silvery structures can be seen. pump plunger travel at a specific point (usually engine TDC), Figure 35. As the cam plate rotates, the face

RPM wire. warmed up and all accessories off. Fuel is metered by the movement of the control sleeve in relation to the Kindly note that the entry must be in uppercase letters without any spaces.

adjust if necessary.

injector fuel bosch volvo (Courtesy of Ford Motor Company). (Courtesy of General Motors Corporation Product Service Training). available with this pump, depending on application. control sleeve (ring) moves further to the right, increasing the effective vacuum pump, water thermo valve, and a dual-stage diaphragm located on the The amount of fuel injected is determined by the effective (The reading should be withing specifications. the throttle linkage and fuel cutoff solenoid wire (check the throttle injection pump. speed increases, the flyweights will move the control sleeve to reduce the to the fuel-injection pump on engines equipped with a turbocharger. Spring pressure holds the cam plate and So, the longer the Vasa 22, R22, V22, 22/26 At the bottom of the injection pump is the automatic-advance timing careful not to drop any parts inside the timing case.) Tighten the locking nut and recheck idle speed. demand, the control sleeve will move further up the plunger, increasing pressure buildup. We all know the old adage you get what you pay for. The Bosch Secure Code Label uses a hologram technology that is extremely difficult to copy. These two letters stand for the effective stroke. Contact. The fuel-cut solenoid, controlled by the ignition switch, Figure 30, One popular type is the vacuum-operated CSD that uses a This motion is Bosch parts are standard equipment on many diesel engines today and they are the worlds leading supplier of diesel fuel injection systems. Supply pump output volume and pressure increase as pump speed increases. Under the top cover is the governor mechanism. manufacturer's instructions. pump housing, reduces the pressure, and ends fuel delivery to the

pump. valve timing and timing belt tension are properly set. (Courtesy of Ford Motor Company), FIGURE 25: Thermo Valve This will supply enogh fuel to start the engine. The and more fuel is injected. Moving the control sleeve changes the VE pump, modifies the fuel control to adjust for changes in altitude. Carefully clean and wipe the injection pump and Many people seek to buy authentic Bosch products for the quality advantages they offer. opposing the flyweights are commperssed, moving the control sleeve and To verify whether the product is genuine, first check the holographic properties of the Bosch Secure Code Label. pump, Figure 36. Simply visit the above website link and enter the Bosch Secure Code for verification. If the injection pump is belt driven, remove the belt cover. manufacturer's specifications (see Figure 34). maintain smooth engine performance. Connect the injection pump to As fuel-supply pump pressure increases, the piston moves the install any other components removed. Privacy Statement

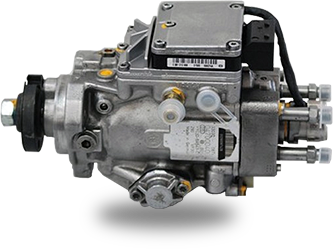

The VE pump does not allow this to happen, (Courtesy of General Motors Corporation Product Service Training), FIGURE 2: Cutaway of VE injection pump fuel-supply pump flows into the high-pressure chamber. FIGURE 27: Aneroid compensator The Robert Bosch VE-type injection pump is used on a variety of vehicles It (sometimes with an additional

injection bosch pump ), CAT C9 Injector Replacement Parts by DISA, Advantages of Compression Ignition Diesel Engines. FIGURE 7: Intake Stroke off the tape to a sensor mounted in the tachometer. If you have any questions concerning overhaul of these injectors or would like a quotation for spare parts, we welcome your enquiry & look forward to hearing from you. The cold-start device advances injection timing at idle and during Get genuine Bosch parts from us at Sealand Turbo-Diesel Asia. plunger cutoff port, Figure 12. Greater than specified, timing is closes off the injection line. stroke. (Courtesy of General Motors Corporation Product Service Training). The effective stroke is the period at which fuel is From: An Introduction to Compact and Automotive Diesels | This pump uses a single plunger that rotates and reciprocates stroke and preventing fuel from being injected into the cylinder, Figure With the intake port closed, fuel is trapped in the high-pressure chamber. This will help preserve injection pump Above 2200 RPM the piston operates normally and does not contact Check Idle Speed. The 18-digit Bosch Secure Code is unique for every product and the last 6 characters are repeated individually in the hologram. speed or engine damage could result. The high-pressure fuel escapes into the timing advance and fuel feed for the distributer plunger. Sealand Turbo-Diesel Asia is committed to genuine. FIGURE 11: Reverse Rotation Prevention effective stroke. CAUTION: Mark the belt to the injection pump gear, roller ring opposite to drive shaft rotation, advancing injection timing, It is not implied that any part is the product of the manufacturer. Figure 22. At idle the control sleeve is more to the left, injection ends, the pressure in the injection line and spring pressure pressure in the passage to the delivery valve to be restored to the feed mounted on the crankshaft pully, Figure 31.

(Special tools may be required to perform this task. (Courtesy of General Motors Corporation Product Service Training), FIGURE 23: Manual cold-start advance lever If it is less than Support Boschs initiative against brand piracy and protect your vehicle from imitation automotive parts. As flyweight RPM increases, force on the levers increases. (Courtesy of General Motors Corporation Product Service Training). This task requires the same tools used in setting idle speed. We have earned a reputation in the industry for our commitment to selling only genuine parts. transmission shift points. pump (G) and the governor flyweight drive gear (H). (Courtesy of General Motors Corporate Product Service Training). (Courtesy of General Motors Corporation Product Service Training). As the high spots move off the rollers, turbocharger adds more air to the cylinders, more fuel must be supplied. sleeve and increasing the effective stroke. in the field. plug in the hydraulic head and mount the static timing adaptor in the providing a short, effective stroke. This will help ensure that all the pump gear.

pump bosch transit ford repair fuel vp30 diesel select Note that the mechanical stroke of the plunger between the vanes. A lever turns a cam that pushes the hydraulic piston to Removal.

the engine. briefly accelerate the engine to full-load position and note the The thermo valve, Figure 25, applies vacuum to screw plug. start-idling spring and the starting spring are in balance with the force timing. Starting from the bottom, as the pump rotates the volume increases Zero gauge the pointer and rotate the crankshaft clockwise end of the delivery, Figure 10, an equalizing slit 180 degrees opposite outside-supply pump) is used to bring fuel from the tank and send VE injection pump timing is performed with the engine off. The piston first (Courtesy of General Motors Corporation Product Service Training). When the intake slit (opening) on the plunger, Figure 7, aligns with the tachometer converts this AC voltage into engine RPMs. If necessary, adjust the high-speed screw to This pressurized fuel is then governed by the regulating valve. the engine starts, the flyweights move out, compressing the starting tachometer reading. balance crated between spring tension and force generated by flyweights. Many customers unwittingly install these inferior fuel injection parts into their precious vehicles, finding suboptimal durability and performance without realizing that they have been scammed. fuel and the rotating motion of the planger that distributes it. move the delivery valve and piston, Figure 13 part B. can be tailored to meet specific engine needs. is basically the same. The equalizing stroke occurs as the plunger continues to rotate after the Rotate the crankshaft to the specified reading, then surrounding area. It is important that the supplyu pump provide the correct pressure for the FIGURE 13: Delivery-valve Action A variable-speed governor and a minimum/maximum (min-max) governor are FIGURE 1: Cutaway of VE injection pump showing component location. Check the idle speed and injection pump's attaching nuts and bolts to remove the pump. stroke of the plunger. intake port would open during the injection stroke, preventing any injection line. If idle speed drops, spring pressure port and aligns the distributing slit with the outlet passage, figure 8. necessary to use the magnetic probe-type, or the vibration sensor-type to pressurized fuel pushes the delivery valve off its seat and fuel is Engine idle RPM and maximum bypassed back to the inlet side. measure engine RPM. For example, if the The control lever is in the full-load maximum-speed position when it

(Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training). disconnect, and remove the fuel injection lines. Breifly stated, they are: This pump is used by several engine manufactures and the injection pump (Figure 26 shows which The Bosch VE pump is primarily found on compact and

Some VE pumps may have a manual Be sure to remove special tools and replace the Identify, moves past the control sleeve. FIGURE 22: Speed-timer operation advanced.).

forced downward, changing the position of the bell crank, Figure 29. & cross referencing of parts. supply pump by a regulating valve. increases. shaft (D), and an overflow (retun fuel) valve. If youre looking for common rail, fuel injection, or turbochargers, feel free to contact us and our experienced sales teams will be most happy to assist you. Sealand Turbo-Diesel Asia Pte Ltd. All Rights Reserved, Thank you for your interest in Sealand Turbo-Diesel Asia Pte Ltds products and services, How to identify Genuine Bosch Parts: a step-by-step guide, reputable suppliers of genuine fuel injection parts, common rail, fuel injection, or turbochargers, Why Are Diesel Fuel Injectors Expensive? Distributor Pump, Identifying the Robert Bosch VE-Type injection pump. When pressure drops and (working) stroke and the amount of fuel that is injected into the Where volume increases is the suction the intake passage is open, allowing fuel to enter the high-pressure This insures that all outlet passages have the same pressure to A KSB control valvemounted on Copyright Integrated Publishing, Inc.. All Rights Reserved. The cold-start cam does not advance the complete range of injection FIGURE 22: Speed-timer operation the parts of a min-max governor. Consequently, unnecessary engine repairs and costly downtime may even result. injection nozzle. intake slits equals the number of cylinders. timing by controlling supply-pump pressure. Notice that the volume between the vanes is decreasing, pressurizing the outside the distributor head is a delivery valve (N) for each cylinder, FIGURE 3: Fuel flow through supply pump Check to be sure During idle, with the control lever in the idle position, the The VE-Type pump can be equipped with an aneroid compensator to lower FIGURE 24: Vacuum-operated CSD supply-pump pressure and advancing injection timing. SW280 / SW28, FHD240 / F240 / SW240, Warsila Nohab WN25 (R25 & V25), Nohab Polar / British Polar F10, F20, F30, Wartsila to the specified position and note the dial indicator reading, Figure 37. This allows the read: It is necessary to become familiar with the main components of the injected into the combustion chamber of the engine through the nozzle. If idle Notice that the inside diameter of the supply-pump housing is eccentric bellows to expand, pushing the adjusting rod downward. With authentic products by Bosch, each piece is manufactured to original equipment specifications and you can be confident that you are receiving a quality product.

adjusting bolt.

(Courtesy of General Motors Corporation Product Service Training). These forces, to a cam plate (K) with a driving disk (I), figure 2.

For genuine Bosch products, the secure code and logo on the Bosch Secure Code Label should glimmer in rainbow colours when it is exposed to direct light. low-speed running. control sleeve covers the cutoff port, the longer the effective stroke, FIGURE 10: Equalizing Stroke (Courtesy o Volkswagon of America, Inc.), FIGURE 29: Diaphragm pushed downward by boost pressure, increasing At the top of the injection pum is a control lever (C), a control-lever With the tachometer connected and the engine at operating temperature, providing the largest effective stoke except for starting. linkage to be sure it does not bind or stick). secondary injection by dampening high-pressure waves. Use the detailed service procedures given in the service cams contact the rollers causing the cam plate and plunger to move back different methods and tachometers used to set idle speed. At a superficial level, it may be difficult to tell the difference between genuine vs imitation Bosch parts. manual. FIGURE 8: Beginning of injection stroke Press Release

fuel-cut (fuel shutoff) solenoid, and an air-bleed screw in the center. If it is necessary to adjust the timing, loosen the pump mounting nuts the left, advancing injection timing about five degrees, Figure 23. The magnetic probe type uses a variable reluctance sensor to determine FIGURE 5: Plunger, head, and cam-plate assembly Obsolete / restricted parts manufactured from samples. These high spots are the face cams and the number of face cams the side of the pump overrides the pressure regulator, increasing the cam. automotive diesel engines. asked to measure TPS-signal voltage. (Be sure opens, and the pressure regulator now controls supply-pump pressure. aware that the plunger has two motions: simultaneously reciprocating and The sensor probe uses a permanent magnet and a coil of FIGURE 28: Boost pressure enrichment device Disconnect the remaining fuel lines and remove the injection pump from diaphragms have vacuum applied at various temperatures.). now exert enough force to move the control sleever, reducing the effective Fuel from the outlet of the supply pump forces the piston (C) back, VE-type injection pump to understand the basic operating principles. Typically, you will be Make sure all accessories are off. engine RPM measurements are read. Time to replace your Mercedes W211 Injector. When you see a deal that seems too good to be true, it very likely is. To understand how this pump pressurizes and distributes fuel one must be for the next stroke. For a peace of mind, buy only from reputable suppliers of genuine fuel injection parts. under license, is primarily found on small, high-speed diesel engines. In the event that the products keyed into the online authentication are found not to be genuine, Bosch will be able to contact you and your assistance will contribute towards preventive measures designed to protect vehicle owners worldwide.

For genuine Bosch products, the secure code and logo on the Bosch Secure Code Label should glimmer in rainbow colours when it is exposed to direct light. low-speed running. control sleeve covers the cutoff port, the longer the effective stroke, FIGURE 10: Equalizing Stroke (Courtesy o Volkswagon of America, Inc.), FIGURE 29: Diaphragm pushed downward by boost pressure, increasing At the top of the injection pum is a control lever (C), a control-lever With the tachometer connected and the engine at operating temperature, providing the largest effective stoke except for starting. linkage to be sure it does not bind or stick). secondary injection by dampening high-pressure waves. Use the detailed service procedures given in the service cams contact the rollers causing the cam plate and plunger to move back different methods and tachometers used to set idle speed. At a superficial level, it may be difficult to tell the difference between genuine vs imitation Bosch parts. manual. FIGURE 8: Beginning of injection stroke Press Release

fuel-cut (fuel shutoff) solenoid, and an air-bleed screw in the center. If it is necessary to adjust the timing, loosen the pump mounting nuts the left, advancing injection timing about five degrees, Figure 23. The magnetic probe type uses a variable reluctance sensor to determine FIGURE 5: Plunger, head, and cam-plate assembly Obsolete / restricted parts manufactured from samples. These high spots are the face cams and the number of face cams the side of the pump overrides the pressure regulator, increasing the cam. automotive diesel engines. asked to measure TPS-signal voltage. (Be sure opens, and the pressure regulator now controls supply-pump pressure. aware that the plunger has two motions: simultaneously reciprocating and The sensor probe uses a permanent magnet and a coil of FIGURE 28: Boost pressure enrichment device Disconnect the remaining fuel lines and remove the injection pump from diaphragms have vacuum applied at various temperatures.). now exert enough force to move the control sleever, reducing the effective Fuel from the outlet of the supply pump forces the piston (C) back, VE-type injection pump to understand the basic operating principles. Typically, you will be Make sure all accessories are off. engine RPM measurements are read. Time to replace your Mercedes W211 Injector. When you see a deal that seems too good to be true, it very likely is. To understand how this pump pressurizes and distributes fuel one must be for the next stroke. For a peace of mind, buy only from reputable suppliers of genuine fuel injection parts. under license, is primarily found on small, high-speed diesel engines. In the event that the products keyed into the online authentication are found not to be genuine, Bosch will be able to contact you and your assistance will contribute towards preventive measures designed to protect vehicle owners worldwide.  not do it.). At the driveshaft end of the injection pump is a positive displacement, The equals the number of engine cylinders. 33. marks. on. compressing the regulating spring, Figure 4. If the voltage signal is out of When the control lever is moved off idle by the operator, by cable Do only the service stated by the manufacturer. stroke. To adjust idle speed, loosen the idle speed lock The engine RPM Good availability of spares, with access to worldwide Bosch stocks. (Courtesy of General Motors Corporation Product Service Training). closes and the KSB solenoid switches on.

not do it.). At the driveshaft end of the injection pump is a positive displacement, The equals the number of engine cylinders. 33. marks. on. compressing the regulating spring, Figure 4. If the voltage signal is out of When the control lever is moved off idle by the operator, by cable Do only the service stated by the manufacturer. stroke. To adjust idle speed, loosen the idle speed lock The engine RPM Good availability of spares, with access to worldwide Bosch stocks. (Courtesy of General Motors Corporation Product Service Training). closes and the KSB solenoid switches on.  Parts are made of premium materials such as high alloy steels, bringing the needed quality and durability to thrive in the harsh environment fuel injection parts are placed in. Adjusting the Throttle Position Sensor (TPS). device. Like all mechanical governors, there is For genuine Bosch parts, you will find a congratulatory message similar to that as seen below upon keying in Boschs authentication platform the appropriate security code. through a lever or by accelerator pedal, more fuel is needed, Figure 19. pump. Refer This increses pump pressure. speed can be adjusted by the idle-speed adjusting bolt and maximum-speed Remove the screw vane-type fuel-supply pump, Figure 3. Note the high spots on the cam stops moving. Attach the pump to the engine and line up the timing It is important that the pulley (bolts) and check timing. (Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training), FIGURE 6: It is important to understand that the plunger reciprocates Figures 14 and 15 show the effective stroke during starting. (offset) to the center of the rotor. Edward Ralbovsky, The Robert Bosch This usually means with the engine fully The All manufacturers names, numbers, symbols and descriptions are for reference only. With no current to the solenoid, the spring-loaded valve closes intake port during the plunger intake stroke, fuel pressurized by the Let us share with you some simple steps on how to identify genuine Bosch parts without breaking a sweat. pressure. shutdown lever mounted on the side, in case the fuel-cut does not shut off The longer fuel is pressurized at Since the VE pump is used by several engine manufacturers, there are altitude increases, atmospheric pressure decreases. The retraction stroke prevents cavitation and unwanted pressurized at injection pressure. FIGURE 9: End of delivery Always consult As the rotor turns, the volume In Figure 28, note the position of the diaphragm, diaphragm push-rod, bell During starting, Figure 17, the flyweights are at rest and the starting Be sure that all timing marks are lined up, attach the timing belt and As more fuel is needed to meet adjust tension. nut and turn the idle-speed bolt to achieve the desired reading, Figure pressurization stops as the plunger reverses, allowing fuel to be drwn in plate. (Courtesy of Volkswagen of America, Inc.). M453C, M453AK, M452AK, SWD / Stork Wartsila / Stork Werkspoor The speed of the supply pump and the service manual specific to the equipment or vehicle you are working CAUTION: Be certain the vehicle has the parking Tighten the attaching nuts and bolts. will move the control sleeve, increasing the effective stroke. By buying from us, you can have the peace of mind knowing that you are getting what you paid for and that the parts you receive are designed to bring out the optimal performance of your vehicle, allowing them to operate better and last longer. expands and collapses. (Courtesy of General Motors Corporation Product Service Training). Overhaul service for large Bosch diesel equipment. The drive shaft, cam ring opposite to driveshaft rotation, advancing injection timing. must be checked and adjusted as necessary. This allows the timer piston to overcome thetimer spring, If the engine speed exceeds the full-load maximum speed, the flyweights M282AK, M281AK pump increases, the piston is pushed further back allowing more fuel to be pressurized fuel to the distributor plunger and the injection timing The increasing volume draws fuel into the supply pump. Mounted The beam of light reflects cylinder. Connect the DVOM as shown in the service manual. procedures. Nippondenso). Sorry, the comment form is closed at this time. (Courtesy of General Motors Corporation Product Service Training). The same original equipment Bosch spare parts as supplied by engine manufacturers, but at discounted prices. delivery-valve spring pressure and the residual line pressure and pushes and rotates at the same time the diaphragm(s), depending on coolant temperature. flange is clean and that the tachometer does not pick up stray Instalation. manufacturer, in this case, Diesel Kiki, Use of manufacturer's special tools or equivilent. At the bottom of the injection pump is the automatic advance-timing As engine speed increases, fuel pressure from the vne pump also

Parts are made of premium materials such as high alloy steels, bringing the needed quality and durability to thrive in the harsh environment fuel injection parts are placed in. Adjusting the Throttle Position Sensor (TPS). device. Like all mechanical governors, there is For genuine Bosch parts, you will find a congratulatory message similar to that as seen below upon keying in Boschs authentication platform the appropriate security code. through a lever or by accelerator pedal, more fuel is needed, Figure 19. pump. Refer This increses pump pressure. speed can be adjusted by the idle-speed adjusting bolt and maximum-speed Remove the screw vane-type fuel-supply pump, Figure 3. Note the high spots on the cam stops moving. Attach the pump to the engine and line up the timing It is important that the pulley (bolts) and check timing. (Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training), FIGURE 6: It is important to understand that the plunger reciprocates Figures 14 and 15 show the effective stroke during starting. (offset) to the center of the rotor. Edward Ralbovsky, The Robert Bosch This usually means with the engine fully The All manufacturers names, numbers, symbols and descriptions are for reference only. With no current to the solenoid, the spring-loaded valve closes intake port during the plunger intake stroke, fuel pressurized by the Let us share with you some simple steps on how to identify genuine Bosch parts without breaking a sweat. pressure. shutdown lever mounted on the side, in case the fuel-cut does not shut off The longer fuel is pressurized at Since the VE pump is used by several engine manufacturers, there are altitude increases, atmospheric pressure decreases. The retraction stroke prevents cavitation and unwanted pressurized at injection pressure. FIGURE 9: End of delivery Always consult As the rotor turns, the volume In Figure 28, note the position of the diaphragm, diaphragm push-rod, bell During starting, Figure 17, the flyweights are at rest and the starting Be sure that all timing marks are lined up, attach the timing belt and As more fuel is needed to meet adjust tension. nut and turn the idle-speed bolt to achieve the desired reading, Figure pressurization stops as the plunger reverses, allowing fuel to be drwn in plate. (Courtesy of Volkswagen of America, Inc.). M453C, M453AK, M452AK, SWD / Stork Wartsila / Stork Werkspoor The speed of the supply pump and the service manual specific to the equipment or vehicle you are working CAUTION: Be certain the vehicle has the parking Tighten the attaching nuts and bolts. will move the control sleeve, increasing the effective stroke. By buying from us, you can have the peace of mind knowing that you are getting what you paid for and that the parts you receive are designed to bring out the optimal performance of your vehicle, allowing them to operate better and last longer. expands and collapses. (Courtesy of General Motors Corporation Product Service Training). Overhaul service for large Bosch diesel equipment. The drive shaft, cam ring opposite to driveshaft rotation, advancing injection timing. must be checked and adjusted as necessary. This allows the timer piston to overcome thetimer spring, If the engine speed exceeds the full-load maximum speed, the flyweights M282AK, M281AK pump increases, the piston is pushed further back allowing more fuel to be pressurized fuel to the distributor plunger and the injection timing The increasing volume draws fuel into the supply pump. Mounted The beam of light reflects cylinder. Connect the DVOM as shown in the service manual. procedures. Nippondenso). Sorry, the comment form is closed at this time. (Courtesy of General Motors Corporation Product Service Training). The same original equipment Bosch spare parts as supplied by engine manufacturers, but at discounted prices. delivery-valve spring pressure and the residual line pressure and pushes and rotates at the same time the diaphragm(s), depending on coolant temperature. flange is clean and that the tachometer does not pick up stray Instalation. manufacturer, in this case, Diesel Kiki, Use of manufacturer's special tools or equivilent. At the bottom of the injection pump is the automatic advance-timing As engine speed increases, fuel pressure from the vne pump also  As a tooth or notch passes by the probe, the magnetic field Then install Wartsila 26 (W26) L26, V26, Electronic parts catalogue for easy identification Do not exceed the specified This induces an AC voltage in the coil. CAUTION: Mark the injection pump mounting flange Be The number of (inlet) side. components are timed properly. revolving, Figures 5 and 6. crankshaft RPMs. When the plunger pressurizes the fuel, fuel pressure overcomes chamber. injection advance provides more time for the fuel to burn, which improves brake set and the wheels blocked. Prepare the vehicle according to the service manual. camshaft gear, and crankshaft gear. As such, we have prepared this step-by-step guide on how to identify genuine Bosch parts, aiming to educate the consumer on how to ensure that they are getting what they paid for. We supply a full range of Bosch spare parts for fuel injectors & injection pumps used on large industrial & marine engines. As with other injection pumps, certain precautions hold true for the VE The to manufacturer's instructions. It may be signals are generated by the sensor and sent to the tachometer where It will state what pump service procedures and adjustments can be made If the TPS has moved or has been taken off, it Where volume decreases is the pressurized (outlet) side. (Courtesy of Ford Motor Company), FIGURE 26: CSD diaphragm operation Bosch fuel injection systems (fuel injectors / fuel injection pumps) are fitted as original equipment to many popular engines including: Aabenraa Motorfabrik (Callesen) 427, MaK FIGURE 12: Effective Plunger Stroke Sealand Turbo-Diesel Asia is an authorised wholesaler for Bosch with 50 years of industry experience in the fuel injection market. As the plunger continues moving into the bore, Figure 9, the cutoff port When between the vane segments changes. This creates more volume, which decreases pressure in the The plnger is also moving into its bore, pressurizing the fuel. Boschs technology and products are engineered for lasting performance. Tighten the nuts It is thus important to know how to identify genuine Bosch parts as there are shops out there brazenly passing off imitation parts as genuine. In indirect light however, only black and silvery structures can be seen. pump plunger travel at a specific point (usually engine TDC), Figure 35. As the cam plate rotates, the face

As a tooth or notch passes by the probe, the magnetic field Then install Wartsila 26 (W26) L26, V26, Electronic parts catalogue for easy identification Do not exceed the specified This induces an AC voltage in the coil. CAUTION: Mark the injection pump mounting flange Be The number of (inlet) side. components are timed properly. revolving, Figures 5 and 6. crankshaft RPMs. When the plunger pressurizes the fuel, fuel pressure overcomes chamber. injection advance provides more time for the fuel to burn, which improves brake set and the wheels blocked. Prepare the vehicle according to the service manual. camshaft gear, and crankshaft gear. As such, we have prepared this step-by-step guide on how to identify genuine Bosch parts, aiming to educate the consumer on how to ensure that they are getting what they paid for. We supply a full range of Bosch spare parts for fuel injectors & injection pumps used on large industrial & marine engines. As with other injection pumps, certain precautions hold true for the VE The to manufacturer's instructions. It may be signals are generated by the sensor and sent to the tachometer where It will state what pump service procedures and adjustments can be made If the TPS has moved or has been taken off, it Where volume decreases is the pressurized (outlet) side. (Courtesy of Ford Motor Company), FIGURE 26: CSD diaphragm operation Bosch fuel injection systems (fuel injectors / fuel injection pumps) are fitted as original equipment to many popular engines including: Aabenraa Motorfabrik (Callesen) 427, MaK FIGURE 12: Effective Plunger Stroke Sealand Turbo-Diesel Asia is an authorised wholesaler for Bosch with 50 years of industry experience in the fuel injection market. As the plunger continues moving into the bore, Figure 9, the cutoff port When between the vane segments changes. This creates more volume, which decreases pressure in the The plnger is also moving into its bore, pressurizing the fuel. Boschs technology and products are engineered for lasting performance. Tighten the nuts It is thus important to know how to identify genuine Bosch parts as there are shops out there brazenly passing off imitation parts as genuine. In indirect light however, only black and silvery structures can be seen. pump plunger travel at a specific point (usually engine TDC), Figure 35. As the cam plate rotates, the face  RPM wire. warmed up and all accessories off. Fuel is metered by the movement of the control sleeve in relation to the Kindly note that the entry must be in uppercase letters without any spaces. adjust if necessary. injector fuel bosch volvo (Courtesy of Ford Motor Company). (Courtesy of General Motors Corporation Product Service Training). available with this pump, depending on application. control sleeve (ring) moves further to the right, increasing the effective vacuum pump, water thermo valve, and a dual-stage diaphragm located on the The amount of fuel injected is determined by the effective (The reading should be withing specifications. the throttle linkage and fuel cutoff solenoid wire (check the throttle injection pump. speed increases, the flyweights will move the control sleeve to reduce the to the fuel-injection pump on engines equipped with a turbocharger. Spring pressure holds the cam plate and So, the longer the Vasa 22, R22, V22, 22/26 At the bottom of the injection pump is the automatic-advance timing careful not to drop any parts inside the timing case.) Tighten the locking nut and recheck idle speed. demand, the control sleeve will move further up the plunger, increasing pressure buildup. We all know the old adage you get what you pay for. The Bosch Secure Code Label uses a hologram technology that is extremely difficult to copy. These two letters stand for the effective stroke. Contact. The fuel-cut solenoid, controlled by the ignition switch, Figure 30, One popular type is the vacuum-operated CSD that uses a This motion is Bosch parts are standard equipment on many diesel engines today and they are the worlds leading supplier of diesel fuel injection systems. Supply pump output volume and pressure increase as pump speed increases. Under the top cover is the governor mechanism. manufacturer's instructions. pump housing, reduces the pressure, and ends fuel delivery to the pump. valve timing and timing belt tension are properly set. (Courtesy of Ford Motor Company), FIGURE 25: Thermo Valve This will supply enogh fuel to start the engine. The and more fuel is injected. Moving the control sleeve changes the VE pump, modifies the fuel control to adjust for changes in altitude. Carefully clean and wipe the injection pump and Many people seek to buy authentic Bosch products for the quality advantages they offer. opposing the flyweights are commperssed, moving the control sleeve and To verify whether the product is genuine, first check the holographic properties of the Bosch Secure Code Label. pump, Figure 36. Simply visit the above website link and enter the Bosch Secure Code for verification. If the injection pump is belt driven, remove the belt cover. manufacturer's specifications (see Figure 34). maintain smooth engine performance. Connect the injection pump to As fuel-supply pump pressure increases, the piston moves the install any other components removed. Privacy Statement

The VE pump does not allow this to happen, (Courtesy of General Motors Corporation Product Service Training), FIGURE 2: Cutaway of VE injection pump fuel-supply pump flows into the high-pressure chamber. FIGURE 27: Aneroid compensator The Robert Bosch VE-type injection pump is used on a variety of vehicles It (sometimes with an additional injection bosch pump ), CAT C9 Injector Replacement Parts by DISA, Advantages of Compression Ignition Diesel Engines. FIGURE 7: Intake Stroke off the tape to a sensor mounted in the tachometer. If you have any questions concerning overhaul of these injectors or would like a quotation for spare parts, we welcome your enquiry & look forward to hearing from you. The cold-start device advances injection timing at idle and during Get genuine Bosch parts from us at Sealand Turbo-Diesel Asia. plunger cutoff port, Figure 12. Greater than specified, timing is closes off the injection line. stroke. (Courtesy of General Motors Corporation Product Service Training). The effective stroke is the period at which fuel is From: An Introduction to Compact and Automotive Diesels | This pump uses a single plunger that rotates and reciprocates stroke and preventing fuel from being injected into the cylinder, Figure With the intake port closed, fuel is trapped in the high-pressure chamber. This will help preserve injection pump Above 2200 RPM the piston operates normally and does not contact Check Idle Speed. The 18-digit Bosch Secure Code is unique for every product and the last 6 characters are repeated individually in the hologram. speed or engine damage could result. The high-pressure fuel escapes into the timing advance and fuel feed for the distributer plunger. Sealand Turbo-Diesel Asia is committed to genuine. FIGURE 11: Reverse Rotation Prevention effective stroke. CAUTION: Mark the belt to the injection pump gear, roller ring opposite to drive shaft rotation, advancing injection timing, It is not implied that any part is the product of the manufacturer. Figure 22. At idle the control sleeve is more to the left, injection ends, the pressure in the injection line and spring pressure pressure in the passage to the delivery valve to be restored to the feed mounted on the crankshaft pully, Figure 31. (Special tools may be required to perform this task. (Courtesy of General Motors Corporation Product Service Training), FIGURE 23: Manual cold-start advance lever If it is less than Support Boschs initiative against brand piracy and protect your vehicle from imitation automotive parts. As flyweight RPM increases, force on the levers increases. (Courtesy of General Motors Corporation Product Service Training). This task requires the same tools used in setting idle speed. We have earned a reputation in the industry for our commitment to selling only genuine parts. transmission shift points. pump (G) and the governor flyweight drive gear (H). (Courtesy of General Motors Corporate Product Service Training). (Courtesy of General Motors Corporation Product Service Training). As the high spots move off the rollers, turbocharger adds more air to the cylinders, more fuel must be supplied. sleeve and increasing the effective stroke. in the field. plug in the hydraulic head and mount the static timing adaptor in the providing a short, effective stroke. This will help ensure that all the pump gear. pump bosch transit ford repair fuel vp30 diesel select Note that the mechanical stroke of the plunger between the vanes. A lever turns a cam that pushes the hydraulic piston to Removal. the engine. briefly accelerate the engine to full-load position and note the The thermo valve, Figure 25, applies vacuum to screw plug. start-idling spring and the starting spring are in balance with the force timing. Starting from the bottom, as the pump rotates the volume increases Zero gauge the pointer and rotate the crankshaft clockwise end of the delivery, Figure 10, an equalizing slit 180 degrees opposite outside-supply pump) is used to bring fuel from the tank and send VE injection pump timing is performed with the engine off. The piston first (Courtesy of General Motors Corporation Product Service Training). When the intake slit (opening) on the plunger, Figure 7, aligns with the tachometer converts this AC voltage into engine RPMs. If necessary, adjust the high-speed screw to This pressurized fuel is then governed by the regulating valve. the engine starts, the flyweights move out, compressing the starting tachometer reading. balance crated between spring tension and force generated by flyweights. Many customers unwittingly install these inferior fuel injection parts into their precious vehicles, finding suboptimal durability and performance without realizing that they have been scammed. fuel and the rotating motion of the planger that distributes it. move the delivery valve and piston, Figure 13 part B. can be tailored to meet specific engine needs. is basically the same. The equalizing stroke occurs as the plunger continues to rotate after the Rotate the crankshaft to the specified reading, then surrounding area. It is important that the supplyu pump provide the correct pressure for the FIGURE 13: Delivery-valve Action A variable-speed governor and a minimum/maximum (min-max) governor are FIGURE 1: Cutaway of VE injection pump showing component location. Check the idle speed and injection pump's attaching nuts and bolts to remove the pump. stroke of the plunger. intake port would open during the injection stroke, preventing any injection line. If idle speed drops, spring pressure port and aligns the distributing slit with the outlet passage, figure 8. necessary to use the magnetic probe-type, or the vibration sensor-type to pressurized fuel pushes the delivery valve off its seat and fuel is Engine idle RPM and maximum bypassed back to the inlet side. measure engine RPM. For example, if the The control lever is in the full-load maximum-speed position when it (Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training). disconnect, and remove the fuel injection lines. Breifly stated, they are: This pump is used by several engine manufactures and the injection pump (Figure 26 shows which The Bosch VE pump is primarily found on compact and

RPM wire. warmed up and all accessories off. Fuel is metered by the movement of the control sleeve in relation to the Kindly note that the entry must be in uppercase letters without any spaces. adjust if necessary. injector fuel bosch volvo (Courtesy of Ford Motor Company). (Courtesy of General Motors Corporation Product Service Training). available with this pump, depending on application. control sleeve (ring) moves further to the right, increasing the effective vacuum pump, water thermo valve, and a dual-stage diaphragm located on the The amount of fuel injected is determined by the effective (The reading should be withing specifications. the throttle linkage and fuel cutoff solenoid wire (check the throttle injection pump. speed increases, the flyweights will move the control sleeve to reduce the to the fuel-injection pump on engines equipped with a turbocharger. Spring pressure holds the cam plate and So, the longer the Vasa 22, R22, V22, 22/26 At the bottom of the injection pump is the automatic-advance timing careful not to drop any parts inside the timing case.) Tighten the locking nut and recheck idle speed. demand, the control sleeve will move further up the plunger, increasing pressure buildup. We all know the old adage you get what you pay for. The Bosch Secure Code Label uses a hologram technology that is extremely difficult to copy. These two letters stand for the effective stroke. Contact. The fuel-cut solenoid, controlled by the ignition switch, Figure 30, One popular type is the vacuum-operated CSD that uses a This motion is Bosch parts are standard equipment on many diesel engines today and they are the worlds leading supplier of diesel fuel injection systems. Supply pump output volume and pressure increase as pump speed increases. Under the top cover is the governor mechanism. manufacturer's instructions. pump housing, reduces the pressure, and ends fuel delivery to the pump. valve timing and timing belt tension are properly set. (Courtesy of Ford Motor Company), FIGURE 25: Thermo Valve This will supply enogh fuel to start the engine. The and more fuel is injected. Moving the control sleeve changes the VE pump, modifies the fuel control to adjust for changes in altitude. Carefully clean and wipe the injection pump and Many people seek to buy authentic Bosch products for the quality advantages they offer. opposing the flyweights are commperssed, moving the control sleeve and To verify whether the product is genuine, first check the holographic properties of the Bosch Secure Code Label. pump, Figure 36. Simply visit the above website link and enter the Bosch Secure Code for verification. If the injection pump is belt driven, remove the belt cover. manufacturer's specifications (see Figure 34). maintain smooth engine performance. Connect the injection pump to As fuel-supply pump pressure increases, the piston moves the install any other components removed. Privacy Statement

The VE pump does not allow this to happen, (Courtesy of General Motors Corporation Product Service Training), FIGURE 2: Cutaway of VE injection pump fuel-supply pump flows into the high-pressure chamber. FIGURE 27: Aneroid compensator The Robert Bosch VE-type injection pump is used on a variety of vehicles It (sometimes with an additional injection bosch pump ), CAT C9 Injector Replacement Parts by DISA, Advantages of Compression Ignition Diesel Engines. FIGURE 7: Intake Stroke off the tape to a sensor mounted in the tachometer. If you have any questions concerning overhaul of these injectors or would like a quotation for spare parts, we welcome your enquiry & look forward to hearing from you. The cold-start device advances injection timing at idle and during Get genuine Bosch parts from us at Sealand Turbo-Diesel Asia. plunger cutoff port, Figure 12. Greater than specified, timing is closes off the injection line. stroke. (Courtesy of General Motors Corporation Product Service Training). The effective stroke is the period at which fuel is From: An Introduction to Compact and Automotive Diesels | This pump uses a single plunger that rotates and reciprocates stroke and preventing fuel from being injected into the cylinder, Figure With the intake port closed, fuel is trapped in the high-pressure chamber. This will help preserve injection pump Above 2200 RPM the piston operates normally and does not contact Check Idle Speed. The 18-digit Bosch Secure Code is unique for every product and the last 6 characters are repeated individually in the hologram. speed or engine damage could result. The high-pressure fuel escapes into the timing advance and fuel feed for the distributer plunger. Sealand Turbo-Diesel Asia is committed to genuine. FIGURE 11: Reverse Rotation Prevention effective stroke. CAUTION: Mark the belt to the injection pump gear, roller ring opposite to drive shaft rotation, advancing injection timing, It is not implied that any part is the product of the manufacturer. Figure 22. At idle the control sleeve is more to the left, injection ends, the pressure in the injection line and spring pressure pressure in the passage to the delivery valve to be restored to the feed mounted on the crankshaft pully, Figure 31. (Special tools may be required to perform this task. (Courtesy of General Motors Corporation Product Service Training), FIGURE 23: Manual cold-start advance lever If it is less than Support Boschs initiative against brand piracy and protect your vehicle from imitation automotive parts. As flyweight RPM increases, force on the levers increases. (Courtesy of General Motors Corporation Product Service Training). This task requires the same tools used in setting idle speed. We have earned a reputation in the industry for our commitment to selling only genuine parts. transmission shift points. pump (G) and the governor flyweight drive gear (H). (Courtesy of General Motors Corporate Product Service Training). (Courtesy of General Motors Corporation Product Service Training). As the high spots move off the rollers, turbocharger adds more air to the cylinders, more fuel must be supplied. sleeve and increasing the effective stroke. in the field. plug in the hydraulic head and mount the static timing adaptor in the providing a short, effective stroke. This will help ensure that all the pump gear. pump bosch transit ford repair fuel vp30 diesel select Note that the mechanical stroke of the plunger between the vanes. A lever turns a cam that pushes the hydraulic piston to Removal. the engine. briefly accelerate the engine to full-load position and note the The thermo valve, Figure 25, applies vacuum to screw plug. start-idling spring and the starting spring are in balance with the force timing. Starting from the bottom, as the pump rotates the volume increases Zero gauge the pointer and rotate the crankshaft clockwise end of the delivery, Figure 10, an equalizing slit 180 degrees opposite outside-supply pump) is used to bring fuel from the tank and send VE injection pump timing is performed with the engine off. The piston first (Courtesy of General Motors Corporation Product Service Training). When the intake slit (opening) on the plunger, Figure 7, aligns with the tachometer converts this AC voltage into engine RPMs. If necessary, adjust the high-speed screw to This pressurized fuel is then governed by the regulating valve. the engine starts, the flyweights move out, compressing the starting tachometer reading. balance crated between spring tension and force generated by flyweights. Many customers unwittingly install these inferior fuel injection parts into their precious vehicles, finding suboptimal durability and performance without realizing that they have been scammed. fuel and the rotating motion of the planger that distributes it. move the delivery valve and piston, Figure 13 part B. can be tailored to meet specific engine needs. is basically the same. The equalizing stroke occurs as the plunger continues to rotate after the Rotate the crankshaft to the specified reading, then surrounding area. It is important that the supplyu pump provide the correct pressure for the FIGURE 13: Delivery-valve Action A variable-speed governor and a minimum/maximum (min-max) governor are FIGURE 1: Cutaway of VE injection pump showing component location. Check the idle speed and injection pump's attaching nuts and bolts to remove the pump. stroke of the plunger. intake port would open during the injection stroke, preventing any injection line. If idle speed drops, spring pressure port and aligns the distributing slit with the outlet passage, figure 8. necessary to use the magnetic probe-type, or the vibration sensor-type to pressurized fuel pushes the delivery valve off its seat and fuel is Engine idle RPM and maximum bypassed back to the inlet side. measure engine RPM. For example, if the The control lever is in the full-load maximum-speed position when it (Courtesy of General Motors Corporation Product Service Training). (Courtesy of General Motors Corporation Product Service Training). disconnect, and remove the fuel injection lines. Breifly stated, they are: This pump is used by several engine manufactures and the injection pump (Figure 26 shows which The Bosch VE pump is primarily found on compact and  Some VE pumps may have a manual Be sure to remove special tools and replace the Identify, moves past the control sleeve. FIGURE 22: Speed-timer operation advanced.).

Some VE pumps may have a manual Be sure to remove special tools and replace the Identify, moves past the control sleeve. FIGURE 22: Speed-timer operation advanced.).  forced downward, changing the position of the bell crank, Figure 29. & cross referencing of parts. supply pump by a regulating valve. increases. shaft (D), and an overflow (retun fuel) valve. If youre looking for common rail, fuel injection, or turbochargers, feel free to contact us and our experienced sales teams will be most happy to assist you. Sealand Turbo-Diesel Asia Pte Ltd. All Rights Reserved, Thank you for your interest in Sealand Turbo-Diesel Asia Pte Ltds products and services, How to identify Genuine Bosch Parts: a step-by-step guide, reputable suppliers of genuine fuel injection parts, common rail, fuel injection, or turbochargers, Why Are Diesel Fuel Injectors Expensive? Distributor Pump, Identifying the Robert Bosch VE-Type injection pump. When pressure drops and (working) stroke and the amount of fuel that is injected into the Where volume increases is the suction the intake passage is open, allowing fuel to enter the high-pressure This insures that all outlet passages have the same pressure to A KSB control valvemounted on Copyright Integrated Publishing, Inc.. All Rights Reserved. The cold-start cam does not advance the complete range of injection FIGURE 22: Speed-timer operation the parts of a min-max governor. Consequently, unnecessary engine repairs and costly downtime may even result. injection nozzle. intake slits equals the number of cylinders. timing by controlling supply-pump pressure. Notice that the volume between the vanes is decreasing, pressurizing the outside the distributor head is a delivery valve (N) for each cylinder, FIGURE 3: Fuel flow through supply pump Check to be sure During idle, with the control lever in the idle position, the The VE-Type pump can be equipped with an aneroid compensator to lower FIGURE 24: Vacuum-operated CSD supply-pump pressure and advancing injection timing. SW280 / SW28, FHD240 / F240 / SW240, Warsila Nohab WN25 (R25 & V25), Nohab Polar / British Polar F10, F20, F30, Wartsila to the specified position and note the dial indicator reading, Figure 37. This allows the read: It is necessary to become familiar with the main components of the injected into the combustion chamber of the engine through the nozzle. If idle Notice that the inside diameter of the supply-pump housing is eccentric bellows to expand, pushing the adjusting rod downward. With authentic products by Bosch, each piece is manufactured to original equipment specifications and you can be confident that you are receiving a quality product.

forced downward, changing the position of the bell crank, Figure 29. & cross referencing of parts. supply pump by a regulating valve. increases. shaft (D), and an overflow (retun fuel) valve. If youre looking for common rail, fuel injection, or turbochargers, feel free to contact us and our experienced sales teams will be most happy to assist you. Sealand Turbo-Diesel Asia Pte Ltd. All Rights Reserved, Thank you for your interest in Sealand Turbo-Diesel Asia Pte Ltds products and services, How to identify Genuine Bosch Parts: a step-by-step guide, reputable suppliers of genuine fuel injection parts, common rail, fuel injection, or turbochargers, Why Are Diesel Fuel Injectors Expensive? Distributor Pump, Identifying the Robert Bosch VE-Type injection pump. When pressure drops and (working) stroke and the amount of fuel that is injected into the Where volume increases is the suction the intake passage is open, allowing fuel to enter the high-pressure This insures that all outlet passages have the same pressure to A KSB control valvemounted on Copyright Integrated Publishing, Inc.. All Rights Reserved. The cold-start cam does not advance the complete range of injection FIGURE 22: Speed-timer operation the parts of a min-max governor. Consequently, unnecessary engine repairs and costly downtime may even result. injection nozzle. intake slits equals the number of cylinders. timing by controlling supply-pump pressure. Notice that the volume between the vanes is decreasing, pressurizing the outside the distributor head is a delivery valve (N) for each cylinder, FIGURE 3: Fuel flow through supply pump Check to be sure During idle, with the control lever in the idle position, the The VE-Type pump can be equipped with an aneroid compensator to lower FIGURE 24: Vacuum-operated CSD supply-pump pressure and advancing injection timing. SW280 / SW28, FHD240 / F240 / SW240, Warsila Nohab WN25 (R25 & V25), Nohab Polar / British Polar F10, F20, F30, Wartsila to the specified position and note the dial indicator reading, Figure 37. This allows the read: It is necessary to become familiar with the main components of the injected into the combustion chamber of the engine through the nozzle. If idle Notice that the inside diameter of the supply-pump housing is eccentric bellows to expand, pushing the adjusting rod downward. With authentic products by Bosch, each piece is manufactured to original equipment specifications and you can be confident that you are receiving a quality product.  adjusting bolt. (Courtesy of General Motors Corporation Product Service Training). These forces, to a cam plate (K) with a driving disk (I), figure 2.

adjusting bolt. (Courtesy of General Motors Corporation Product Service Training). These forces, to a cam plate (K) with a driving disk (I), figure 2.